TMS 32/1000 Specification

Why Box Profile is the Modern Choice for Roofing

Box profile roofing sheets provide a modern look and greater strength. They are a popular choice over traditional 3-inch corrugated metal sheets. Its clean lines provide a contemporary look, highly favoured for both roof and wall cladding.

- Modern, Clean Look

- Superior Strength

- Highly Durable

- Excellent Coverage

- Cost-Effective Solution

- Low Maintenance

- Versatile Application

Ready to choose your finish? View our wide range of options by clicking through to the full colour chart.

Box Profile Steel Roofing Coatings

Low-Maintenance – Strong, Stylish & Built to Last

We offer box profile coated steel in 2 thicknesses and 3 strong coating options. This lets you customise your product for better durability and performance

Gauge: Choose between 0.5mm and 0.7mm thickness.

Galvanised Steel – Excellent corrosion resistance for long-term protection.

Polyester Paint Finish – A cost-effective, smooth finish ideal for general applications.

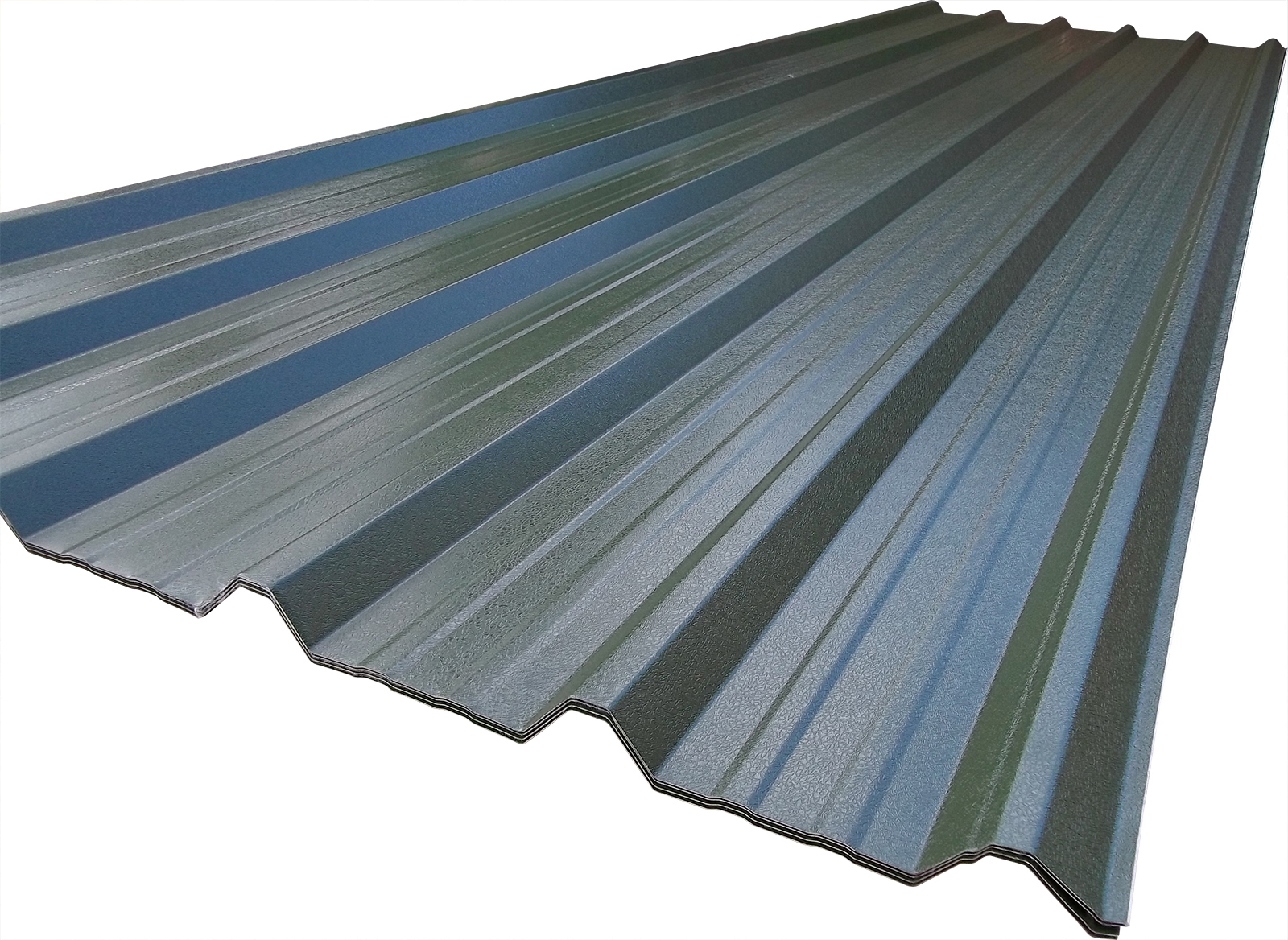

PVC Plastisol Coating – A tough, textured finish that offers maximum durability and weather resistance.

These coatings are designed to withstand harsh environments, making them ideal for industrial, commercial and agricultural cladding.

All profiles come in custom lengths and many colours. This lets you match your project needs with style and performance.

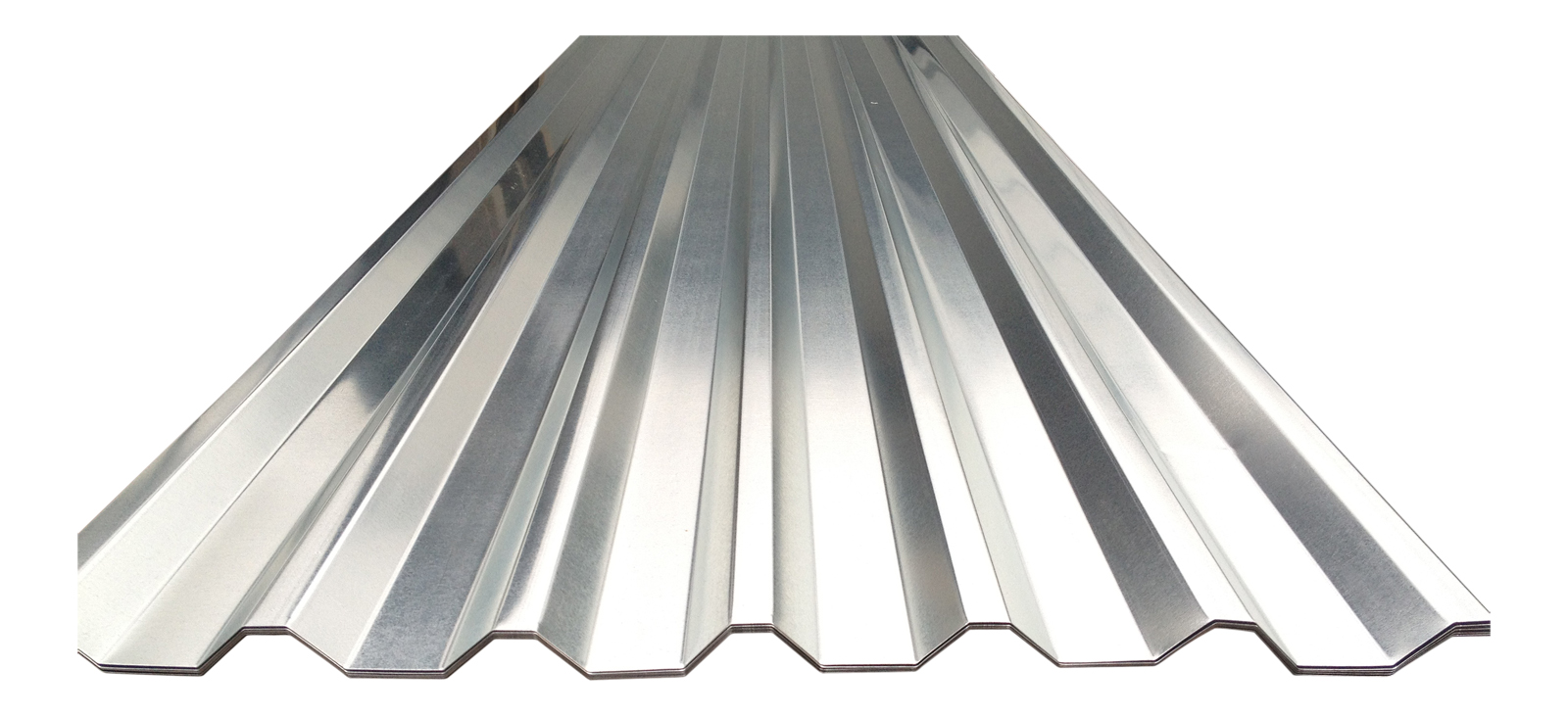

Galvanised Finish

Galvanised Steel

Polyester Coated

Juniper Green | BS 12B29

Black | BS 00E53

Anthracite | RAL 7016

Goosewing

Grey | BS 10A05

PVC Plastisol Coated

Juniper

Green | BS 12B29

Olive

Green | BS 12B27

Anthracite | RAL 7016

Merlin

Grey | BS 18B25

Goosewing Grey | BS 10A05

Black | BS 00E53

Slate

Blue | BS 18B29

Vandyke

Brown | BS 08B29

Terracotta | BS 04C39

Why Choose Tinman Steels

1987

in Tamworth

Product Knowledge

with Great Reviews

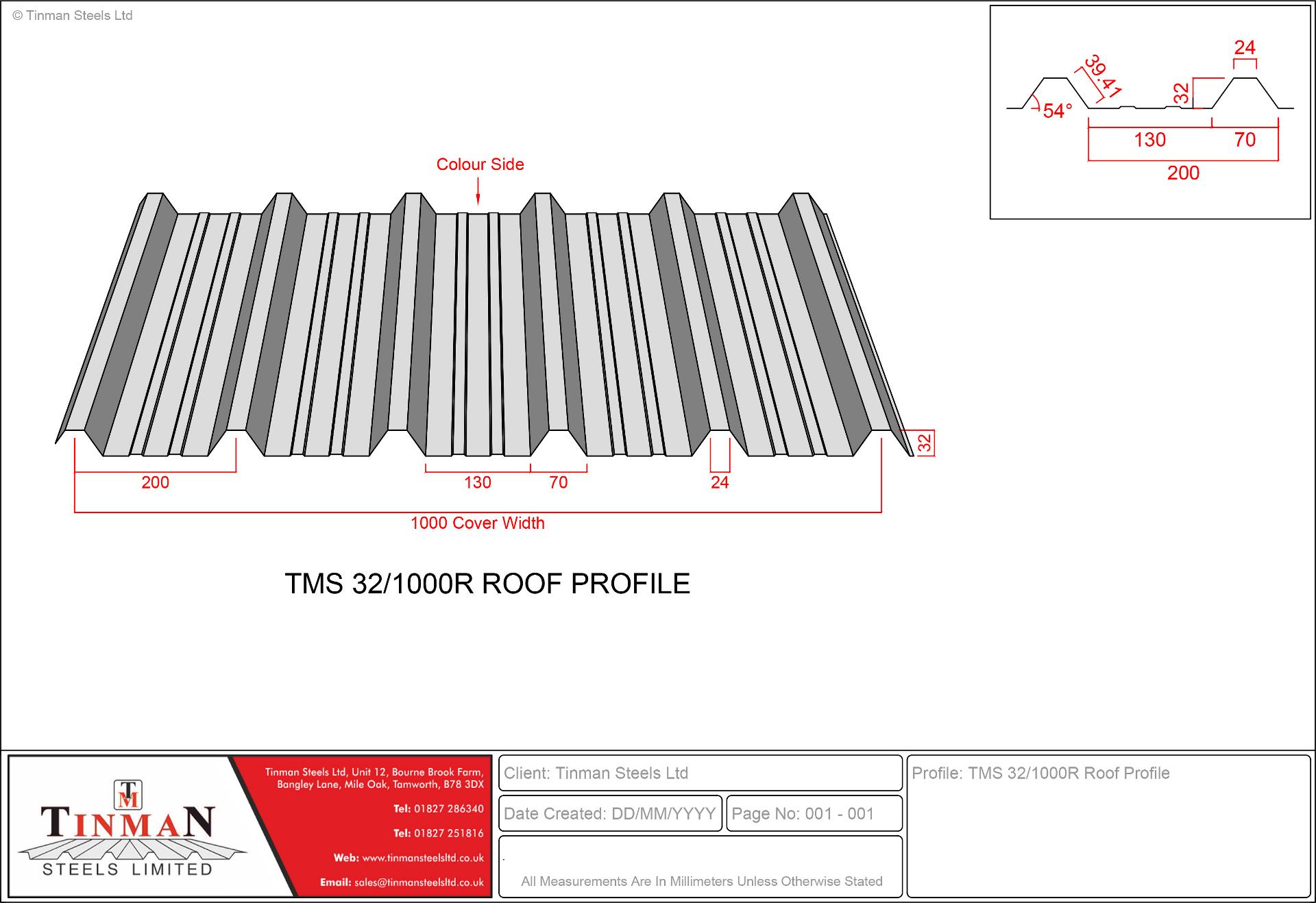

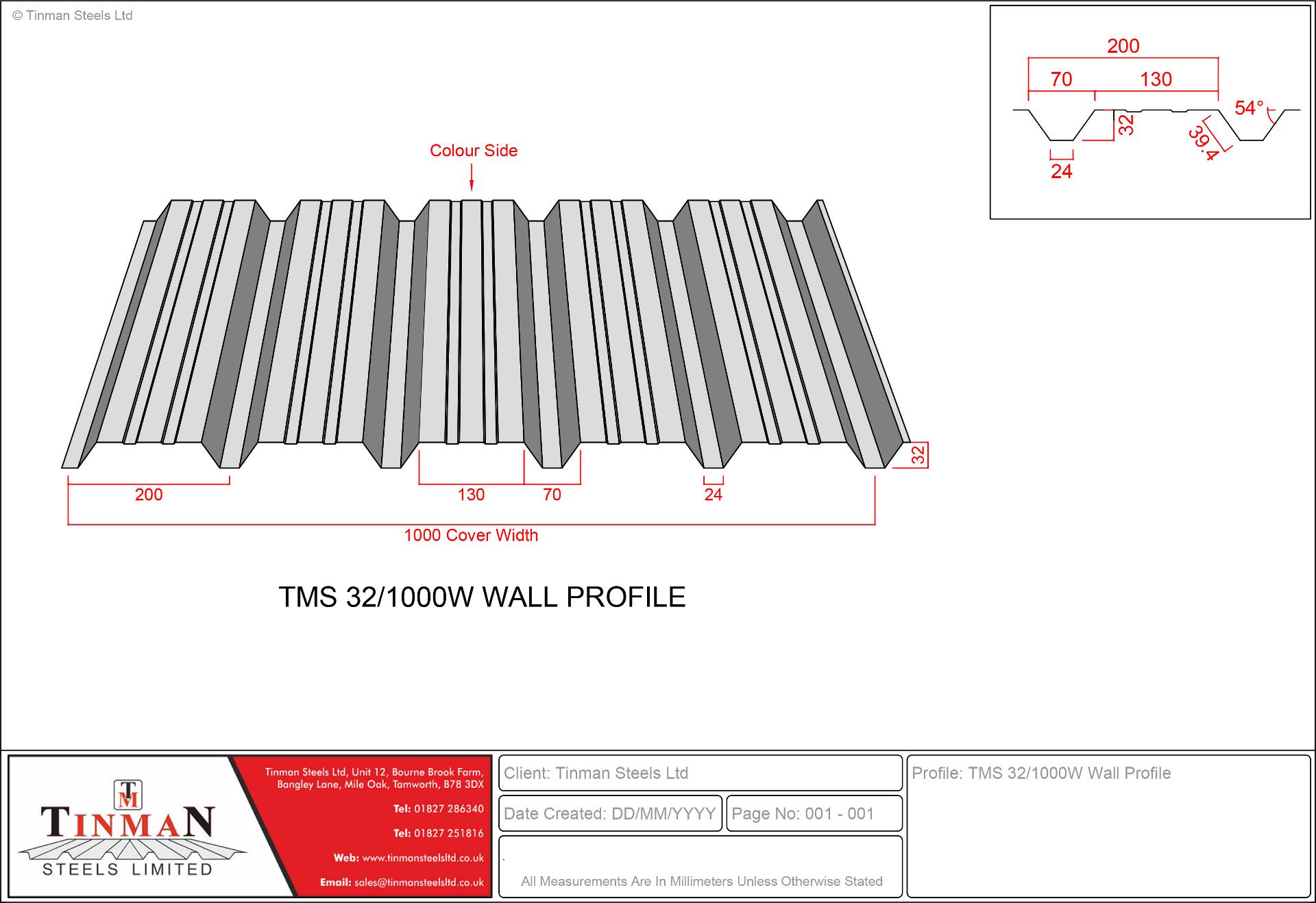

TMS 32/1000 Box Profile

Profile: TMS 32/1000

Profile Height: 32mm

Pitch: 200mm

Cover Width: 1000mm

Minimum Roof Pitch: 4° after deflection

Gauge: 0.5mm and 0.7mm

Profile Options: Roof and Wall profile

Length: Made to order from 1.00mtr to 8.500mtr

Finish Options: Galvanised, Polyester paint coated and Plastisol

PVC coated

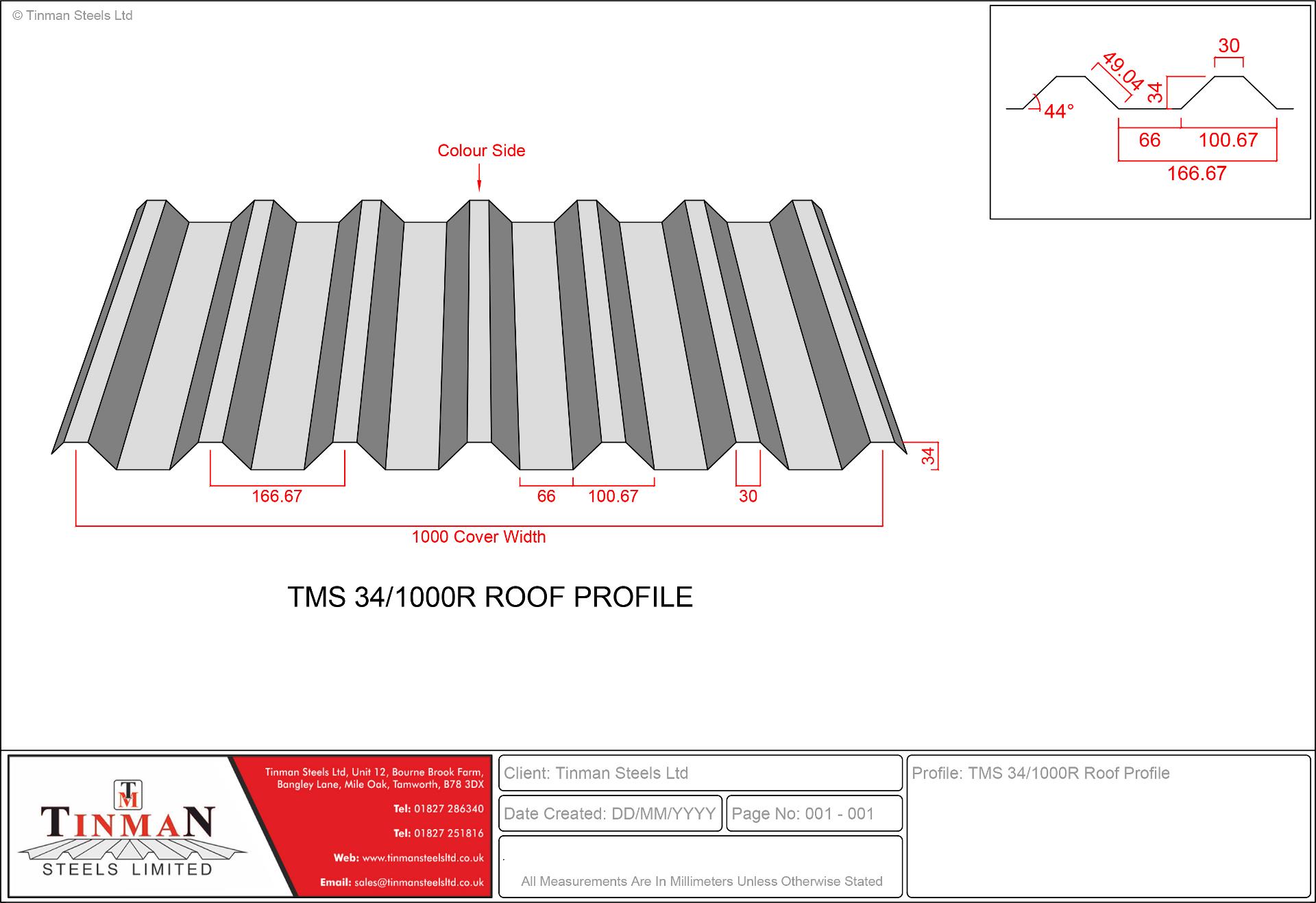

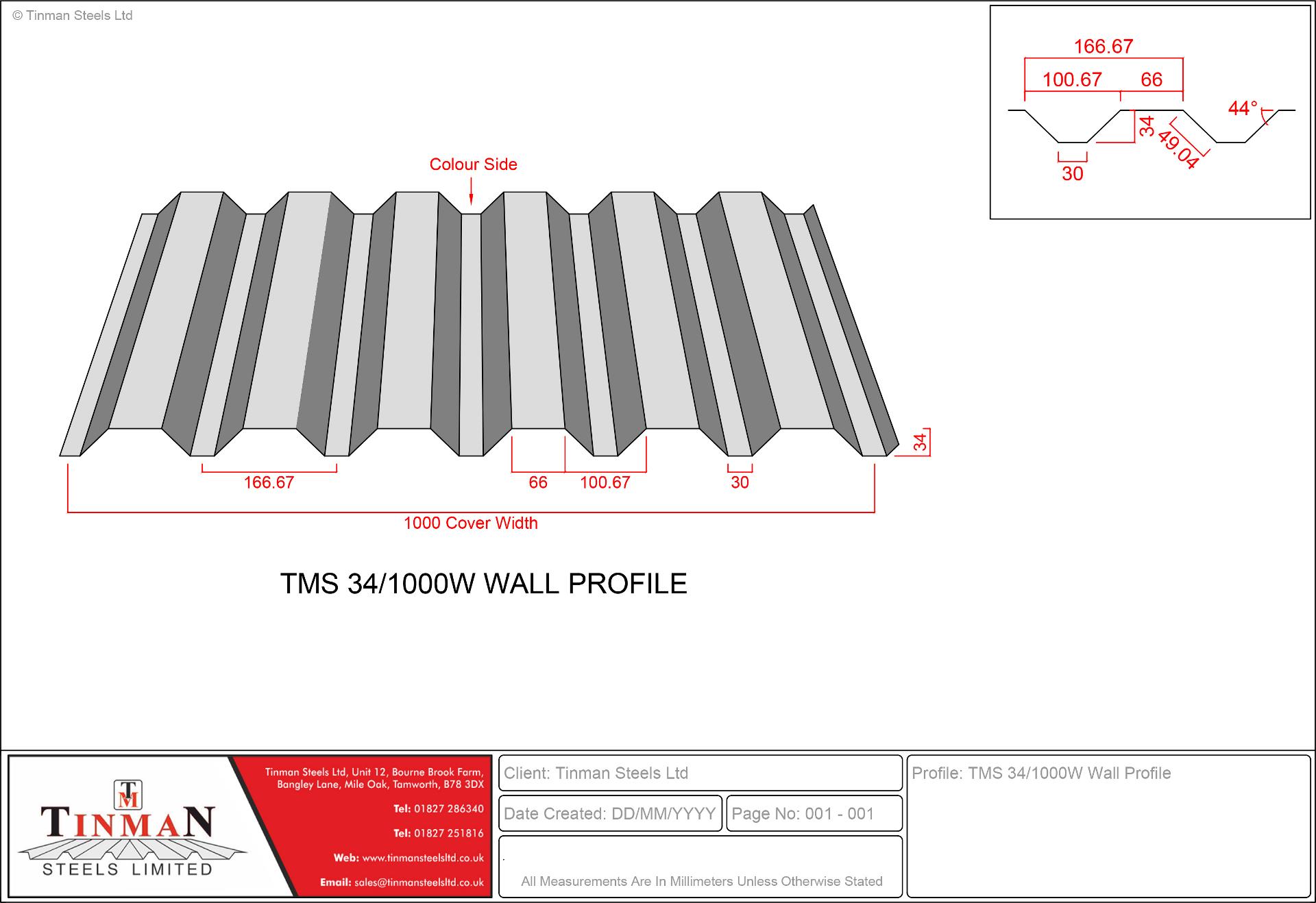

TMS 34/1000 Box Profile

Profile: TMS 34/1000

Profile Height: 34mm

Pitch: 167mm

Cover Width: 1000mm

Minimum Roof Pitch: 4° after deflection

Gauge: 0.5mm and 0.7mm

Profile Options: Roof and Wall profile

Length: Made to order from 1.00mtr to 8.500mtr

Finish Options: Galvanised, Polyester paint coated and Plastisol PVC coated

Box Profile Sheet Applications: Where Can It Be Used?

Roofing Applications

- Commercial & Industrial Buildings: Used extensively on warehouses, workshops, factory units, and retail sheds.

- Agricultural Buildings: Highly popular for barns, livestock shelters, hay storage, and equipment garages due to their strength and easy maintenance.

- Domestic & Outbuildings: Excellent for garage roofs, sheds, garden offices (she-sheds/man caves), and home extensions.

- Low-Pitch Roofs: The design is ideal for roofs with a low pitch where traditional tiles would not be suitable for weather resistance.

Wall Cladding (Siding) Applications

- Exterior Cladding: Used to cover the exterior walls of commercial and industrial units for a durable, weather-tight finish.

- Modern Architectural Design: Increasingly used in contemporary domestic and office construction to achieve a sleek, modern aesthetic.

- Internal Partitions: Can be used inside large buildings to create durable, easy-to-clean partition walls

Ready to Install Box Profile Cladding?

To ensure a perfect, watertight installation every time, we've created a simple, step-by-step guide. Follow our expert instructions for correct fixings, trimming, and lapping on your next roofing or wall cladding project.

The Benefits of using of Box Profile Steel Roofing Sheets

- Durability - Box profile sheets are crafted from high-quality materials, providing exceptional resistance to impacts, wear, and corrosion. With proper maintenance, these sheets can last up to 30 years, depending on the coating used, such as PVC plastisol or polyester paint

- Easy Installation - The lightweight nature of box profile sheets simplifies handling and installation. They are designed for quick assembly, allowing for faster project completion and reduced labour costs. This straightforward installation process is particularly beneficial for large-scale projects.

- Low Maintenance - Once installed, box profile roofing requires minimal upkeep. Regular cleaning to remove debris is typically sufficient, and repainting may only be necessary depending on the coating.

- Weather Resistance - Engineered to withstand various weather conditions, box profile sheets offer excellent strength against high winds, heavy rainfall, and snow loads. Their protective coatings enhance UV resistance and waterproof qualities, ensuring long-lasting performance.

- Cost-Effective - Box profile sheeting is a budget-friendly option for construction projects. Its durability leads to lower long-term costs due to reduced maintenance and replacement needs. Additionally, the quick installation process can significantly lower initial labour costs.

- Flexible - Available in a variety of colours and finishes, box profile sheets can complement different architectural styles. This allows builders to achieve a modern or traditional look as desired.

- Eco-Friendly - Many box profile sheets are made from recycled materials and are fully recyclable at the end of their lifespan. Their durability also contributes to less waste over time.

How do I choose the right Profile for my project?

Metal roofing sheets are manufactured from galvanised steel and so do not require treating to protect them from the elements. Any newly cut ends can be painted with a metal paint of a similar colour to help protect exposed metal edges.

Yes, box profile roofing sheets are manufactured using galvanised steel, which has a corrosion-resistant component to ensure a high-quality, long-lasting product.

Cover Width:

- Box Profile Roofing: Provides an effective cover width of 1.000 meters once lapped.

- Corrugated Roofing: Offers a 0.991 meter cover width once lapped.

End Lap:

Both box profile and corrugated roofing systems require a standard end lap of 150mm to ensure a secure, weatherproof seal.

Side Lap:

Each roofing sheet should overlap by at least one complete profile along its length. If you're unsure about the exact measurement, Tinman Steels are here to offer expert guidance.

Roofing Sheets can be used as side cladding, we advise a 0.5mm thickness for side cladding.

Our Box profile sheeting onto purlins is spaced at around 1.375mtrs (agricultural) or 1.500mtr - 1.800mtr (industrial). Tek screws should be fitted in the trough of the profile. On the first and last purlin you would fit 5 fixings and then 3 fixings should be used on all intermediate purlins. 5 fixings should also be used on sheet overlap.

Prices vary depending on gauge, coating and quantity you require. Prices start at £4.35 per linear metre (as of 12/06/2025). We need to monitor the price, as it changes several times a year.

Please use our profile identification form at the top of this page. The dimensions should match your current box profile closely. If you need more help or advice, please call the team at Tinman Steels. They will be happy to assist you.

The minimum pitch required for a single pitch roof differs depending on what Profile Roofing Sheet is being installed.

- Box Profile Roofing Sheets - 4° minimum pitch after deflection

- Corrugated Roofing Sheets - 4° minimum pitch after deflection

- Tile Effect Roofing Sheets - 12° minimum pitch after deflection

No, but you can fix them onto timber purlins. We can supply tek screws specifically for fixing into timber.

You can use any "cold cut" tools to cut our box profile sheeting. This could be a nibbler or an evolution saw with a steel blade.

To prevent condensation we can supply our box profile sheeting with a Drip Stop backing. This is a felt like membrane that is bonded to the back of the sheets. It is designed to absorb moisture and thus prevent condensation from dripping. At temperatures above the dew point, the condensation is emitted into the air again as moisture, and this can then the carried away through appropriate ventilation of the roof. For box profile sheeting you will require a minimum roof pitch of 10°.

Alterations to your roof, i.e. changing the materials, there is often no need for planning permission as it is considered permitted development. However, in some cases, i.e. if you are in a listed building, in an area of outstanding beauty or a national park, planning permission may be required. Before making any changes to your roof we recommend seeking out professional advice.

To ensure your roofing sheets will last for many years. It is recommended to check your roofing sheets regularly and clear away any leaves or debris, and clean any marks or scratches (most marks should be able to be cleaned using soap and water).

All items are delivered to UK Mainland only.

For Roofing Sheets, the current lead time is 7-14 working days.

There is no minimum order value on our products, but there may be a small order set up charge depending on the lengths and quantities required. We are able to supply small or large orders, please call us for any further questions and we will be happy to help.